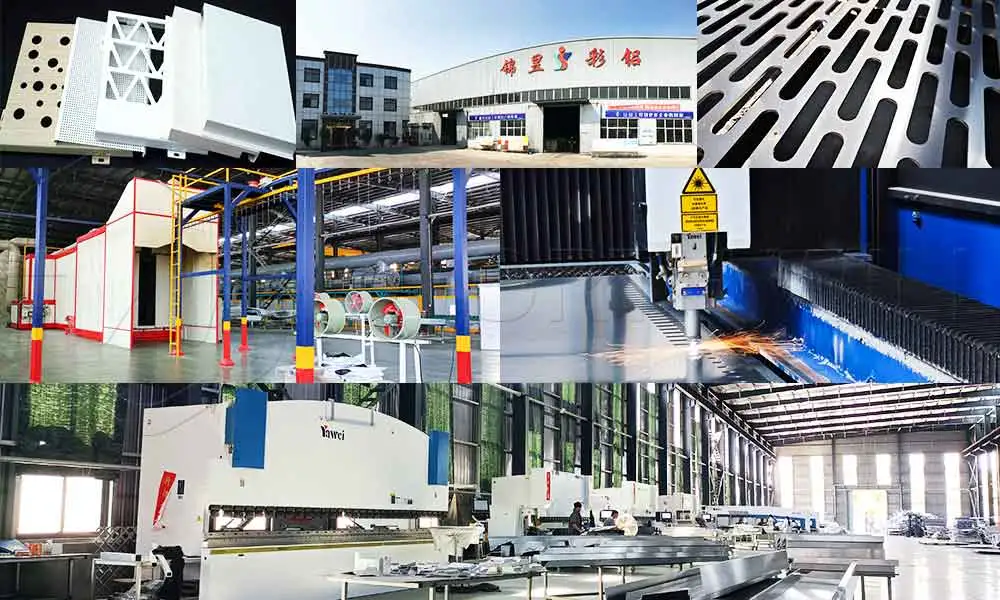

Equipment used in an aluminum cladding factory typically includes a range of machinery and tools to manufacture aluminum cladding products. These may include:

- Rolling Mills: Used to reduce the thickness of aluminum sheets and create uniform thickness for cladding materials.

- Cutting Machines: Various cutting tools like shears or saws have use to cut aluminum sheets to the required sizes and shapes.

- CNC Machines: Computer Numerical Control (CNC) machines have wide for precision cutting, milling, and shaping of aluminum sheets and profiles.

- Presses: Hydraulic or mechanical presses have wide uses for forming and shaping aluminum cladding components.

- Welding Machines: Used for welding aluminum panels or components together to create larger cladding pieces.

- Roll Forming Machines: Used to shape aluminum sheets into specific profiles and designs for cladding.

- Coating Equipment: This may include equipment for applying protective coatings, finishes, or paint to aluminum cladding products.

- Quality Control and Inspection Tools: This includes tools and devices for checking the quality, dimensions, and finish of aluminum cladding products.

- Material Handling Equipment: Such as cranes, forklifts, and conveyors for moving and transporting aluminum sheets and finished products within the factory.

- Extrusion Machines: Used for creating custom profiles and shapes for aluminum cladding components.

- Bending Machines: Used for bending and forming aluminum sheets or profiles into the desired shapes.

- Assembly Stations: Workstations equipped with tools and equipment for assembling different cladding components into final products.

- Safety Equipment: Safety measures and equipment are crucial in any manufacturing facility. Including safety gear for workers and safety systems for machinery.

It’s important to note that the specific equipment used in an aluminum cladding factory can vary depending on the size of the factory. The type of cladding products being produced